On June 19-20, 2019 the Board of Directors of Ilim Group led by Chairman Zakhar Smushkin visited Ilim’s mills in Siberia.

The main purpose of the visit was to assess the progress of the large-scale investment projects in Siberia.

Ust-Ilimsk

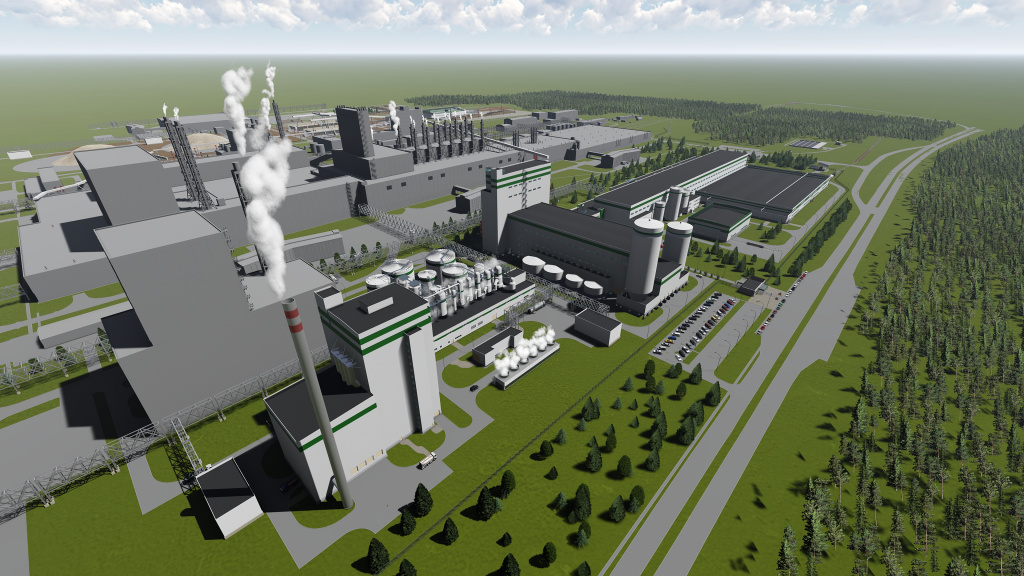

The key item on the Ust-Ilimsk agenda was the visit to the construction site of a future pulp and paperboard mill with a capacity of 600 thousand tons per year. The groundwork is currently in progress, it involves preparation of a foundation for the paper machine area and a finished products warehouse. Ilim has already signed a contract to receive a unique, one of a kind, paper machine that will have a custom design and the highest KLB capacity in the world. Paperboard production in Ust-Ilimsk involves a comprehensive value-added processing of all types of wood (both HW and SW), it is a fully automated cutting-edge production process, which will create 600 new jobs and trigger infrastructure development. The start-up of a new pulp and paperboard mill is scheduled for late 2021 with a CAPEX of RUB 67 billion.

In order to prepare the mill for such a significant technological breakthrough, several important strategic projects aimed to retrofit the existing production process were implemented at the Ust-Ilimsk mill over the last two years. The Board of Directors also visited the evaporators retrofitted last year with a CAPEX exceeding RUB 1 billion. The evaporators are equipped with four liquor concentrators, two new surface condensers, and a distributed control system to facilitate precision operations.

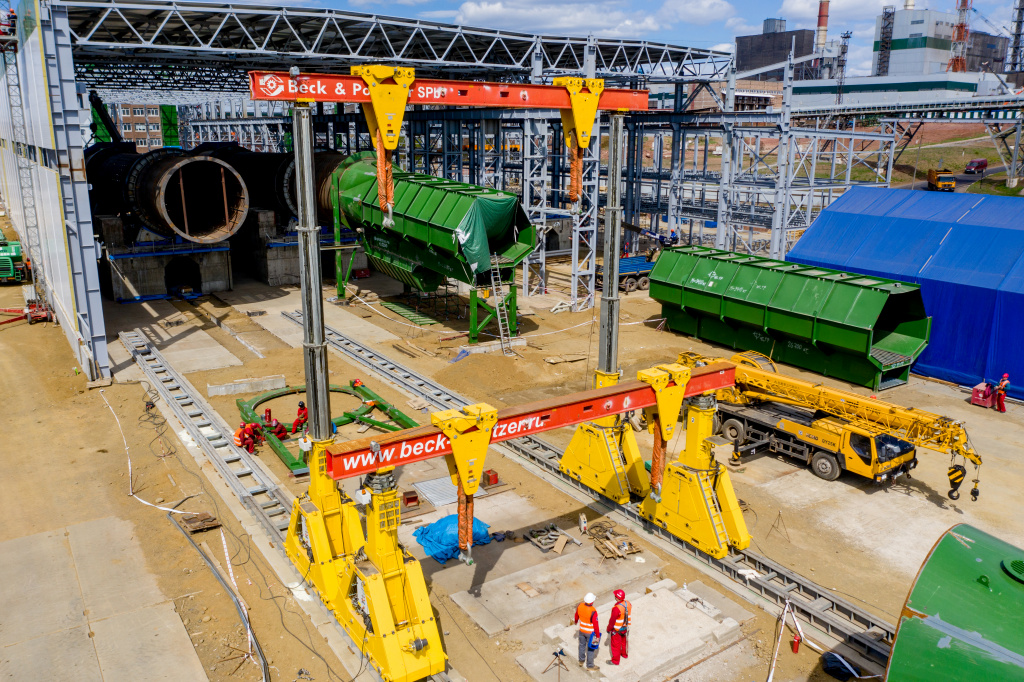

Along with the evaporators, a Recovery Boiler (RB) was also upgraded. The project involved an upgrade of 95% of equipment, including replacement of almost all heating surfaces, installation of superheaters, and upgrade of the automated process control system. Installation of new precipitators significantly reduced dust emissions. Total CAPEX was near RUB 4 billion.

Bratsk

By the end of 2021, total amount of investments into the Bratsk mill projects will reach RUB 38 billion. The KLB line upgrade with a start-up scheduled for late 2019 will be the key project for the Bratsk Mill. This line is, in fact, a new production facility, which will add 110 thousand tons of board to the annual production volumes. At the same time, the Bratsk mill is rebuilding its HW line, which will be completed in 2020 and will increase the annual production volumes by 173 thousand tons.

With a focus on BAT and global best practices, additional facilities are being built to support capacity growth in Bratsk. For example, a new woodyard, which will be placed in service in February 2020, with an aggregate capacity of its 3 lines amounting to 5 million m3 of chips per year will minimize the environmental footprint. The technologies used at the new woodyard will allow to improve chip quality and reduce consumption of resources (electrical energy and water).

The Board of Directors also assessed the progress of another Bratsk mill project, namely the rebuild of two existing evaporators and construction of a new one. This project will allow to reduce the volume of effluents and improve the quality of effluent treatment. Moreover, the project involves an increase in the evaporation capacity, reduction of the environmental footprint and steam and power consumption.

Infrastructure development

The agenda of the Board of Directors visit also included the visit to a new building of the airport in Ust-Ilimsk, the construction of which was sponsored by Ilim Group. In 2018-2019, as part of its social and economic partnership with the Irkutsk Oblast Government, Ilim Group allocated more than RUB 100 million to this project.

Given persistently high passenger traffic and high demand for the flights between Irkutsk and Ust-Ilimsk, the Ministry of Housing, Energy and Transport of Irkutsk Oblast increased the frequency of such flights. Starting from 2019 AN-28 and L-410-type aircraft perform 4 scheduled flights on this route per week.

Reference information:

Ilim’s investment program covers a period of 5 years through 2021, with total investments around RUB 200 billion. As a result of the upgrade of the existing facilities and launch of new capacities, the finished products output will increase by 1 million tons, including 700 thousand tons of packaging materials and 300 thousand tons of market pulp.